Components and supplies

1

Arduino Mega 2560

7

Resistor 220 ohm

Tools and machines

1

Breadboard, 400 Pin

1

Servo Motor, Premium Male/Male Jumper Wires

Project description

Code

2Axis-Digital-Level-V1

arduino

Arduino Code for this project

1// Include Wire Library for I2C 2#include <Wire.h> 3 4// Include for 8X8 Dot Matrix 5#include "LedControl.h" 6LedControl lc = LedControl (6, 5, 4, 1); 7 8//Tolerance 9// 0-10 = Ultra Fast - Loose accuracy but averages ok 10// 11-100 is more acurrate but slower as you scale up. 11const int tolerance = 10; 12 13//Precision 14const float Low4 = -1.00; 15const float Low3 = -0.75; 16const float Low2 = -0.50; 17const float Low1 = -0.25; 18const float High1 = 0.25; 19const float High2 = 0.50; 20const float High3 = 0.75; 21const float High4 = 01.00; 22 23// BreadBoard LED Pins 24int led0 = 7; 25int led1 = 8; 26int led2 = 9; 27int led3 = 10; 28int led4 = 11; 29int led5 = 12; 30int led6 = 13; 31 32// Vars for positioning later 33int row; 34int col; 35 36// Display counter 37int displaycount = 0; 38 39//Variables for Gyroscope 40int gyro_x, gyro_y, gyro_z; 41long gyro_x_cal, gyro_y_cal, gyro_z_cal; 42boolean set_gyro_angles; 43 44long acc_x, acc_y, acc_z, acc_total_vector; 45float angle_roll_acc, angle_pitch_acc; 46 47float angle_pitch, angle_roll; 48int angle_pitch_buffer, angle_roll_buffer; 49float angle_pitch_output, angle_roll_output; 50 51// Setup temp variable 52int temp; 53 54void setup() { 55 56 // the MAX72XX is in power-saving mode on startup, 57 // we have to do a wakeup call 58 lc.shutdown (0, false); 59 60 //Start I2C 61 Wire.begin(); 62 63 // Set Board LEDs as outputs 64 pinMode(led0, OUTPUT); 65 pinMode(led1, OUTPUT); 66 pinMode(led2, OUTPUT); 67 pinMode(led3, OUTPUT); 68 pinMode(led4, OUTPUT); 69 pinMode(led5, OUTPUT); 70 pinMode(led6, OUTPUT); 71 72 //Setup the registers of the MPU-6050 73 setup_mpu_6050_registers(); 74 75 //Read the raw acc and gyro data from the MPU-6050 1000 times 76 for (int cal_int = 0; cal_int < 1000 ; cal_int ++) { 77 read_mpu_6050_data(); 78 //Add the gyro x offset to the gyro_x_cal variable 79 gyro_x_cal += gyro_x; 80 //Add the gyro y offset to the gyro_y_cal variable 81 gyro_y_cal += gyro_y; 82 //Add the gyro z offset to the gyro_z_cal variable 83 gyro_z_cal += gyro_z; 84 //Delay 3us to have 250Hz for-loop 85 delay(3); 86 } 87 88 // Divide all results by 1000 to get average offset 89 gyro_x_cal /= 1000; 90 gyro_y_cal /= 1000; 91 gyro_z_cal /= 1000; 92 93 // Start Serial Monitor 94 Serial.begin(115200); 95 96} 97 98void loop() { 99 100 // Get data from MPU-6050 101 read_mpu_6050_data(); 102 103 //Subtract the offset values from the raw gyro values 104 gyro_x -= gyro_x_cal; 105 gyro_y -= gyro_y_cal; 106 gyro_z -= gyro_z_cal; 107 108 //Gyro angle calculations . Note 0.0000611 = 1 / (250Hz x 65.5) 109 110 //Calculate the traveled pitch angle and add this to the angle_pitch variable 111 angle_pitch += gyro_x * 0.0000611; 112 //Calculate the traveled roll angle and add this to the angle_roll variable 113 //0.000001066 = 0.0000611 * (3.142(PI) / 180degr) The Arduino sin function is in radians 114 angle_roll += gyro_y * 0.0000611; 115 116 //If the IMU has yawed transfer the roll angle to the pitch angle 117 angle_pitch += angle_roll * sin(gyro_z * 0.000001066); 118 //If the IMU has yawed transfer the pitch angle to the roll angle 119 angle_roll -= angle_pitch * sin(gyro_z * 0.000001066); 120 121 //Accelerometer angle calculations 122 123 //Calculate the total accelerometer vector 124 acc_total_vector = sqrt((acc_x * acc_x) + (acc_y * acc_y) + (acc_z * acc_z)); 125 126 //57.296 = 1 / (3.142 / 180) The Arduino asin function is in radians 127 //Calculate the pitch angle 128 angle_pitch_acc = asin((float)acc_y / acc_total_vector) * 57.296; 129 //Calculate the roll angle 130 angle_roll_acc = asin((float)acc_x / acc_total_vector) * -57.296; 131 132 //Accelerometer calibration value for pitch 133 angle_pitch_acc -= 0.0; 134 //Accelerometer calibration value for roll 135 angle_roll_acc -= 0.0; 136 137 if (set_gyro_angles) { 138 139 //If the IMU has been running 140 //Correct the drift of the gyro pitch angle with the accelerometer pitch angle 141 angle_pitch = angle_pitch * 0.9996 + angle_pitch_acc * 0.0004; 142 //Correct the drift of the gyro roll angle with the accelerometer roll angle 143 angle_roll = angle_roll * 0.9996 + angle_roll_acc * 0.0004; 144 } 145 else { 146 //IMU has just started 147 //Set the gyro pitch angle equal to the accelerometer pitch angle 148 angle_pitch = angle_pitch_acc; 149 //Set the gyro roll angle equal to the accelerometer roll angle 150 angle_roll = angle_roll_acc; 151 //Set the IMU started flag 152 set_gyro_angles = true; 153 } 154 155 //To dampen the pitch and roll angles a complementary filter is used 156 //Take 90% of the output pitch value and add 10% of the raw pitch value 157 angle_pitch_output = angle_pitch_output * 0.9 + angle_pitch * 0.1; 158 //Take 90% of the output roll value and add 10% of the raw roll value 159 angle_roll_output = angle_roll_output * 0.9 + angle_roll * 0.1; 160 //Wait until the loop_timer reaches 4000us (250Hz) before starting the next loop 161 162 // Increment the display counter 163 displaycount = displaycount + 1; 164 165 if (displaycount > tolerance) { 166 167 // Print to Serial Monitor 168 Serial.print(" | Pitch: "); Serial.println(angle_pitch_output); 169 Serial.print(" | Roll: "); Serial.println(angle_roll_output); 170 171 // clear the 8X8 display 172 lc.clearDisplay (0); 173 174 // Get position for BoardLEDs and Matrix Row 175 // boardLights: 1 = On, 0 = Off, 176 if (angle_pitch_output < Low4) { 177 boardLights(1, 0, 0, 0, 0, 0, 0); 178 row = 6; 179 } else if ((angle_pitch_output > Low3) && (angle_pitch_output < Low2)) { 180 boardLights(0, 1, 0, 0, 0, 0, 0); 181 row = 5; 182 } else if ((angle_pitch_output > Low2) && (angle_pitch_output < Low1)) { 183 boardLights(0, 0, 1, 0, 0, 0, 0); 184 row = 4; 185 } else if ((angle_pitch_output > Low1) && (angle_pitch_output < High1)) { 186 boardLights(0, 0, 0, 1, 0, 0, 0); 187 row = 3; 188 } else if ((angle_pitch_output > High1) && (angle_pitch_output < High2)) { 189 boardLights(0, 0, 0, 0, 1, 0, 0); 190 row = 2; 191 } else if ((angle_pitch_output > High2) && (angle_pitch_output < High3)) { 192 boardLights(0, 0, 0, 0, 0, 1, 0); 193 row = 1; 194 } else if (angle_pitch_output > High4) { 195 boardLights(0, 0, 0, 0, 0, 0, 1); 196 row = 0; 197 } 198 199 //Get Col Position 200 if (angle_roll_output < Low4) { 201 col = 0; 202 } else if ((angle_roll_output > Low3) && (angle_roll_output < Low2)) { 203 col = 1; 204 } else if ((angle_roll_output > Low2) && (angle_roll_output < Low1)) { 205 col = 2; 206 } else if ((angle_roll_output > Low1) && (angle_roll_output < High1)) { 207 col = 3; 208 } else if ((angle_roll_output > High1) && (angle_roll_output < High2)) { 209 col = 4; 210 } else if ((angle_roll_output > High2) && (angle_roll_output < High3)) { 211 col = 5; 212 } else if (angle_roll_output > High4) { 213 col = 6; 214 } 215 216 // set the brightness to a medium values 217 lc.setIntensity (0, 8); 218 219 //Light Up the 4 LED quadrant of the position of row & col (x & y axis) 220 lc.setLed (0, col, row, true); 221 lc.setLed (0, col + 1, row, true); 222 lc.setLed (0, col, row + 1, true); 223 lc.setLed (0, col + 1, row + 1, true); 224 225 if ((row == 3) && (col == 3)) { 226 lc.setIntensity (0, 16); 227 lc.setRow (0, 0, B11111111); 228 for (int i = 1; i < 7; i++) { 229 lc.setRow (0, i, B10000001); 230 } 231 lc.setRow (0, 7, B11111111); 232 } else { 233 lc.setIntensity (0, 8); 234 lc.setRow (0, 3, B00011000); 235 lc.setRow (0, 4, B00011000); 236 } 237 displaycount = 0; 238 } 239} 240 241void boardLights(int pos0, int pos1, int pos2, int pos3, int pos4, int pos5, int pos6) { 242 digitalWrite(led0, pos0); 243 digitalWrite(led1, pos1); 244 digitalWrite(led2, pos2); 245 digitalWrite(led3, pos3); 246 digitalWrite(led4, pos4); 247 digitalWrite(led5, pos5); 248 digitalWrite(led6, pos6); 249} 250 251void setup_mpu_6050_registers() { 252 253 //Activate the MPU-6050 254 255 //Start communicating with the MPU-6050 256 Wire.beginTransmission(0x68); 257 //Send the requested starting register 258 Wire.write(0x6B); 259 //Set the requested starting register 260 Wire.write(0x00); 261 //End the transmission 262 Wire.endTransmission(); 263 264 //Configure the accelerometer (+/-8g) 265 266 //Start communicating with the MPU-6050 267 Wire.beginTransmission(0x68); 268 //Send the requested starting register 269 Wire.write(0x1C); 270 //Set the requested starting register 271 Wire.write(0x10); 272 //End the transmission 273 Wire.endTransmission(); 274 275 //Configure the gyro (500dps full scale) 276 277 //Start communicating with the MPU-6050 278 Wire.beginTransmission(0x68); 279 //Send the requested starting register 280 Wire.write(0x1B); 281 //Set the requested starting register 282 Wire.write(0x08); 283 //End the transmission 284 Wire.endTransmission(); 285 286} 287 288void read_mpu_6050_data() { 289 290 //Read the raw gyro and accelerometer data 291 292 //Start communicating with the MPU-6050 293 Wire.beginTransmission(0x68); 294 //Send the requested starting register 295 Wire.write(0x3B); 296 //End the transmission 297 Wire.endTransmission(); 298 //Request 14 bytes from the MPU-6050 299 Wire.requestFrom(0x68, 14); 300 //Wait until all the bytes are received 301 while (Wire.available() < 14); 302 303 //Following statements left shift 8 bits, then bitwise OR. 304 //Turns two 8-bit values into one 16-bit value 305 acc_x = Wire.read() << 8 | Wire.read(); 306 acc_y = Wire.read() << 8 | Wire.read(); 307 acc_z = Wire.read() << 8 | Wire.read(); 308 temp = Wire.read() << 8 | Wire.read(); 309 gyro_x = Wire.read() << 8 | Wire.read(); 310 gyro_y = Wire.read() << 8 | Wire.read(); 311 gyro_z = Wire.read() << 8 | Wire.read(); 312}

2Axis-Digital-Level-V1

arduino

Arduino Code for this project

1// Include Wire Library for I2C 2#include <Wire.h> 3 4// Include 5 for 8X8 Dot Matrix 6#include "LedControl.h" 7LedControl lc = LedControl (6, 8 5, 4, 1); 9 10//Tolerance 11// 0-10 = Ultra Fast - Loose accuracy but averages 12 ok 13// 11-100 is more acurrate but slower as you scale up. 14const int tolerance 15 = 10; 16 17//Precision 18const float Low4 = -1.00; 19const float Low3 = -0.75; 20const 21 float Low2 = -0.50; 22const float Low1 = -0.25; 23const float High1 = 0.25; 24const 25 float High2 = 0.50; 26const float High3 = 0.75; 27const float High4 = 01.00; 28 29// 30 BreadBoard LED Pins 31int led0 = 7; 32int led1 = 8; 33int led2 = 9; 34int led3 35 = 10; 36int led4 = 11; 37int led5 = 12; 38int led6 = 13; 39 40// Vars for positioning 41 later 42int row; 43int col; 44 45// Display counter 46int displaycount = 0; 47 48//Variables 49 for Gyroscope 50int gyro_x, gyro_y, gyro_z; 51long gyro_x_cal, gyro_y_cal, gyro_z_cal; 52boolean 53 set_gyro_angles; 54 55long acc_x, acc_y, acc_z, acc_total_vector; 56float angle_roll_acc, 57 angle_pitch_acc; 58 59float angle_pitch, angle_roll; 60int angle_pitch_buffer, 61 angle_roll_buffer; 62float angle_pitch_output, angle_roll_output; 63 64// Setup 65 temp variable 66int temp; 67 68void setup() { 69 70 // the MAX72XX is in power-saving 71 mode on startup, 72 // we have to do a wakeup call 73 lc.shutdown (0, false); 74 75 76 //Start I2C 77 Wire.begin(); 78 79 // Set Board LEDs as outputs 80 pinMode(led0, 81 OUTPUT); 82 pinMode(led1, OUTPUT); 83 pinMode(led2, OUTPUT); 84 pinMode(led3, 85 OUTPUT); 86 pinMode(led4, OUTPUT); 87 pinMode(led5, OUTPUT); 88 pinMode(led6, 89 OUTPUT); 90 91 //Setup the registers of the MPU-6050 92 setup_mpu_6050_registers(); 93 94 95 //Read the raw acc and gyro data from the MPU-6050 1000 times 96 for (int cal_int 97 = 0; cal_int < 1000 ; cal_int ++) { 98 read_mpu_6050_data(); 99 //Add the 100 gyro x offset to the gyro_x_cal variable 101 gyro_x_cal += gyro_x; 102 //Add 103 the gyro y offset to the gyro_y_cal variable 104 gyro_y_cal += gyro_y; 105 //Add 106 the gyro z offset to the gyro_z_cal variable 107 gyro_z_cal += gyro_z; 108 //Delay 109 3us to have 250Hz for-loop 110 delay(3); 111 } 112 113 // Divide all results 114 by 1000 to get average offset 115 gyro_x_cal /= 1000; 116 gyro_y_cal /= 1000; 117 118 gyro_z_cal /= 1000; 119 120 // Start Serial Monitor 121 122 Serial.begin(115200); 123 124} 125 126void loop() { 127 128 // Get data from 129 MPU-6050 130 read_mpu_6050_data(); 131 132 //Subtract the offset values from the 133 raw gyro values 134 gyro_x -= gyro_x_cal; 135 gyro_y -= gyro_y_cal; 136 gyro_z 137 -= gyro_z_cal; 138 139 //Gyro angle calculations . Note 0.0000611 = 1 / (250Hz 140 x 65.5) 141 142 //Calculate the traveled pitch angle and add this to the angle_pitch 143 variable 144 angle_pitch += gyro_x * 0.0000611; 145 //Calculate the traveled roll 146 angle and add this to the angle_roll variable 147 //0.000001066 = 0.0000611 * (3.142(PI) 148 / 180degr) The Arduino sin function is in radians 149 angle_roll += gyro_y * 0.0000611; 150 151 152 //If the IMU has yawed transfer the roll angle to the pitch angle 153 angle_pitch 154 += angle_roll * sin(gyro_z * 0.000001066); 155 //If the IMU has yawed transfer 156 the pitch angle to the roll angle 157 angle_roll -= angle_pitch * sin(gyro_z * 158 0.000001066); 159 160 //Accelerometer angle calculations 161 162 //Calculate the 163 total accelerometer vector 164 acc_total_vector = sqrt((acc_x * acc_x) + (acc_y 165 * acc_y) + (acc_z * acc_z)); 166 167 //57.296 = 1 / (3.142 / 180) The Arduino asin 168 function is in radians 169 //Calculate the pitch angle 170 angle_pitch_acc = asin((float)acc_y 171 / acc_total_vector) * 57.296; 172 //Calculate the roll angle 173 angle_roll_acc 174 = asin((float)acc_x / acc_total_vector) * -57.296; 175 176 //Accelerometer calibration 177 value for pitch 178 angle_pitch_acc -= 0.0; 179 //Accelerometer calibration value 180 for roll 181 angle_roll_acc -= 0.0; 182 183 if (set_gyro_angles) { 184 185 //If 186 the IMU has been running 187 //Correct the drift of the gyro pitch angle with 188 the accelerometer pitch angle 189 angle_pitch = angle_pitch * 0.9996 + angle_pitch_acc 190 * 0.0004; 191 //Correct the drift of the gyro roll angle with the accelerometer 192 roll angle 193 angle_roll = angle_roll * 0.9996 + angle_roll_acc * 0.0004; 194 195 } 196 else { 197 //IMU has just started 198 //Set the gyro pitch angle 199 equal to the accelerometer pitch angle 200 angle_pitch = angle_pitch_acc; 201 202 //Set the gyro roll angle equal to the accelerometer roll angle 203 angle_roll 204 = angle_roll_acc; 205 //Set the IMU started flag 206 set_gyro_angles = true; 207 208 } 209 210 //To dampen the pitch and roll angles a complementary filter is used 211 212 //Take 90% of the output pitch value and add 10% of the raw pitch value 213 angle_pitch_output 214 = angle_pitch_output * 0.9 + angle_pitch * 0.1; 215 //Take 90% of the output roll 216 value and add 10% of the raw roll value 217 angle_roll_output = angle_roll_output 218 * 0.9 + angle_roll * 0.1; 219 //Wait until the loop_timer reaches 4000us (250Hz) 220 before starting the next loop 221 222 // Increment the display counter 223 displaycount 224 = displaycount + 1; 225 226 if (displaycount > tolerance) { 227 228 // Print 229 to Serial Monitor 230 Serial.print(" | Pitch: "); Serial.println(angle_pitch_output); 231 232 Serial.print(" | Roll: "); Serial.println(angle_roll_output); 233 234 235 // clear the 8X8 display 236 lc.clearDisplay (0); 237 238 // Get position 239 for BoardLEDs and Matrix Row 240 // boardLights: 1 = On, 0 = Off, 241 if (angle_pitch_output 242 < Low4) { 243 boardLights(1, 0, 0, 0, 0, 0, 0); 244 row = 6; 245 } 246 else if ((angle_pitch_output > Low3) && (angle_pitch_output < Low2)) { 247 boardLights(0, 248 1, 0, 0, 0, 0, 0); 249 row = 5; 250 } else if ((angle_pitch_output > Low2) 251 && (angle_pitch_output < Low1)) { 252 boardLights(0, 0, 1, 0, 0, 0, 0); 253 254 row = 4; 255 } else if ((angle_pitch_output > Low1) && (angle_pitch_output 256 < High1)) { 257 boardLights(0, 0, 0, 1, 0, 0, 0); 258 row = 3; 259 } 260 else if ((angle_pitch_output > High1) && (angle_pitch_output < High2)) { 261 boardLights(0, 262 0, 0, 0, 1, 0, 0); 263 row = 2; 264 } else if ((angle_pitch_output > High2) 265 && (angle_pitch_output < High3)) { 266 boardLights(0, 0, 0, 0, 0, 1, 0); 267 268 row = 1; 269 } else if (angle_pitch_output > High4) { 270 boardLights(0, 271 0, 0, 0, 0, 0, 1); 272 row = 0; 273 } 274 275 //Get Col Position 276 277 if (angle_roll_output < Low4) { 278 col = 0; 279 } else if ((angle_roll_output 280 > Low3) && (angle_roll_output < Low2)) { 281 col = 1; 282 } else if ((angle_roll_output 283 > Low2) && (angle_roll_output < Low1)) { 284 col = 2; 285 } else if ((angle_roll_output 286 > Low1) && (angle_roll_output < High1)) { 287 col = 3; 288 } else if ((angle_roll_output 289 > High1) && (angle_roll_output < High2)) { 290 col = 4; 291 } else if ((angle_roll_output 292 > High2) && (angle_roll_output < High3)) { 293 col = 5; 294 } else if (angle_roll_output 295 > High4) { 296 col = 6; 297 } 298 299 // set the brightness to a medium 300 values 301 lc.setIntensity (0, 8); 302 303 //Light Up 304 the 4 LED quadrant of the position of row & col (x & y axis) 305 lc.setLed (0, 306 col, row, true); 307 lc.setLed (0, col + 1, row, true); 308 lc.setLed (0, 309 col, row + 1, true); 310 lc.setLed (0, col + 1, row + 1, true); 311 312 if 313 ((row == 3) && (col == 3)) { 314 lc.setIntensity (0, 16); 315 lc.setRow 316 (0, 0, B11111111); 317 for (int i = 1; i < 7; i++) { 318 lc.setRow (0, 319 i, B10000001); 320 } 321 lc.setRow (0, 7, B11111111); 322 } else { 323 324 lc.setIntensity (0, 8); 325 lc.setRow (0, 3, B00011000); 326 lc.setRow 327 (0, 4, B00011000); 328 } 329 displaycount = 0; 330 } 331} 332 333void boardLights(int 334 pos0, int pos1, int pos2, int pos3, int pos4, int pos5, int pos6) { 335 digitalWrite(led0, 336 pos0); 337 digitalWrite(led1, pos1); 338 digitalWrite(led2, pos2); 339 digitalWrite(led3, 340 pos3); 341 digitalWrite(led4, pos4); 342 digitalWrite(led5, pos5); 343 digitalWrite(led6, 344 pos6); 345} 346 347void setup_mpu_6050_registers() { 348 349 //Activate the MPU-6050 350 351 352 //Start communicating with the MPU-6050 353 Wire.beginTransmission(0x68); 354 355 //Send the requested starting register 356 Wire.write(0x6B); 357 //Set the requested 358 starting register 359 Wire.write(0x00); 360 //End the transmission 361 Wire.endTransmission(); 362 363 364 //Configure the accelerometer (+/-8g) 365 366 //Start communicating with the 367 MPU-6050 368 Wire.beginTransmission(0x68); 369 //Send the requested starting register 370 371 Wire.write(0x1C); 372 //Set the requested starting register 373 Wire.write(0x10); 374 375 //End the transmission 376 Wire.endTransmission(); 377 378 //Configure the gyro 379 (500dps full scale) 380 381 //Start communicating with the MPU-6050 382 Wire.beginTransmission(0x68); 383 384 //Send the requested starting register 385 Wire.write(0x1B); 386 //Set the requested 387 starting register 388 Wire.write(0x08); 389 //End the transmission 390 Wire.endTransmission(); 391 392} 393 394void 395 read_mpu_6050_data() { 396 397 //Read the raw gyro and accelerometer data 398 399 400 //Start communicating with the MPU-6050 401 Wire.beginTransmission(0x68); 402 403 //Send the requested starting register 404 Wire.write(0x3B); 405 //End the transmission 406 407 Wire.endTransmission(); 408 //Request 14 bytes from the MPU-6050 409 Wire.requestFrom(0x68, 410 14); 411 //Wait until all the bytes are received 412 while (Wire.available() < 413 14); 414 415 //Following statements left shift 8 bits, then bitwise OR. 416 //Turns 417 two 8-bit values into one 16-bit value 418 acc_x = Wire.read() << 8 | Wire.read(); 419 420 acc_y = Wire.read() << 8 | Wire.read(); 421 acc_z = Wire.read() << 8 | Wire.read(); 422 423 temp = Wire.read() << 8 | Wire.read(); 424 gyro_x = Wire.read() << 8 | Wire.read(); 425 426 gyro_y = Wire.read() << 8 | Wire.read(); 427 gyro_z = Wire.read() << 8 | Wire.read(); 428}

Downloadable files

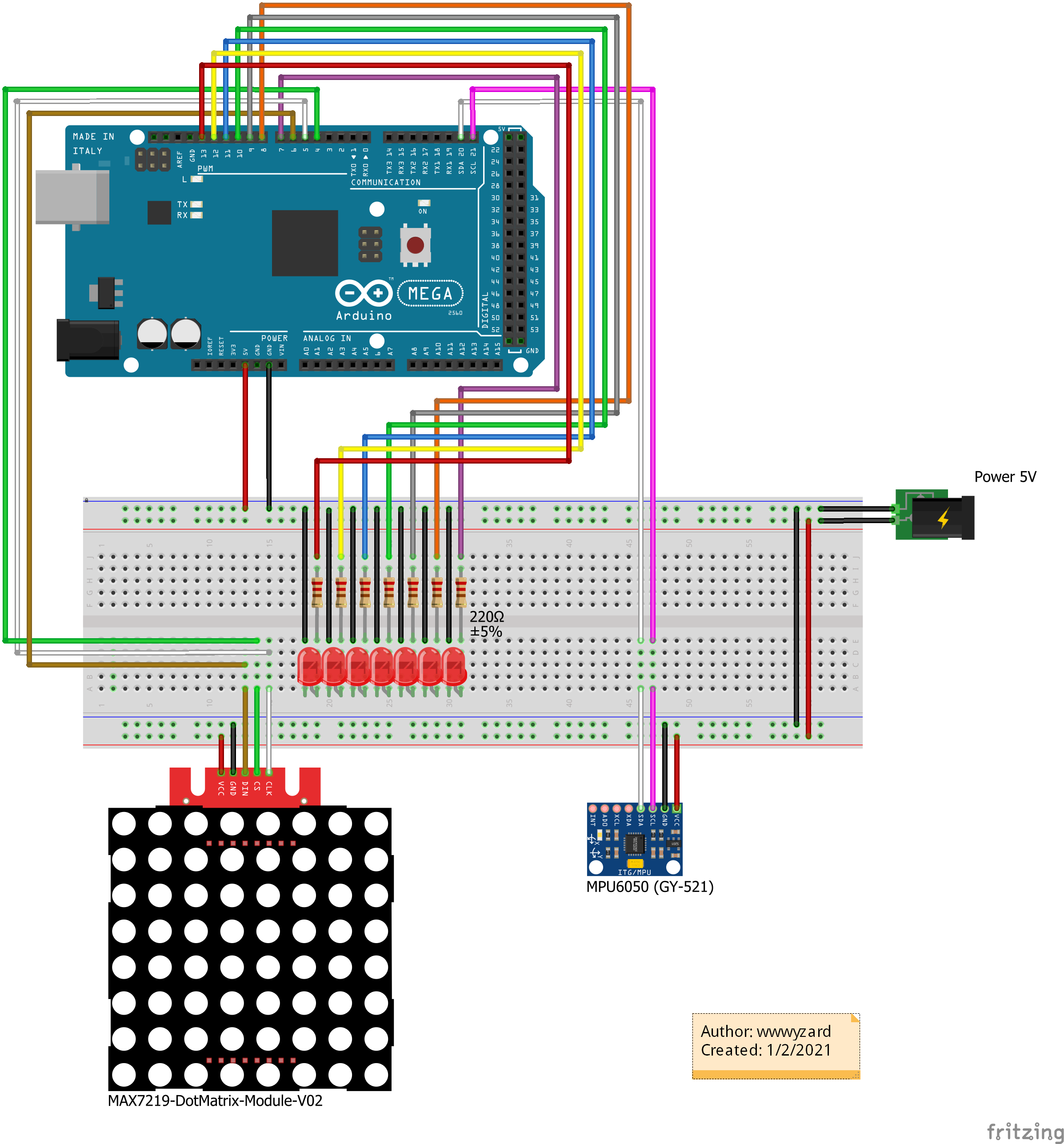

2Axis-Digital-Level-V1

Wiring Diagram for this project

2Axis-Digital-Level-V1

Comments

Only logged in users can leave comments